LRPC - LOW RELAXATION PC STRANDS

Miki Steel is among the leading LRPC strand manufacturers in India and has been producing these wires and strands satisfying the most stringent demands in the industry for years. Our state of the art stabilising process is in pursuant to the globally followed standards of testing LRPC. With this technology now available in India, design and construction engineers are reaping benefits of this critical material on a much wider scale.

LRPC stands for Low Relaxation Pre-stressed steel strands, is the concept of pre-stress steel strands loosing initially applied stress in mathematical proportion with the passage of time when embedded in concrete.

The utmost important factor attributing to this loss in stress is the stress relaxation property of the steel itself. By treating the steel through a thermo-mechanical process known as ‘stabilising’, the propensity of the steel to“Relax” under a stressed condition is controlled to a great extent. Low relaxation ensures that no noticeable loss of tension will occur in time, therefore a long lasting compressive force on concrete.

Our prestressing steel guarantees a very low relaxation. The use of Low Relaxation Strand is well-established in developed countries. However, its use in India was restricted till recently due to limited availability of strands.

Wind Mills |

Metro Bridges |

Bridges |

LNG Tanks |

Buildings |

Atomic Reactors |

Flyovers |

Cement Soils |

Pre-stressed steel strand, when stressed and embedded in concrete, loses the applied stress exponentially as time passes. The loss of stress is called ‘Stress Relaxation’ and is one of the most important factors in the design of pre-stressed concrete structures. If the assumed relaxation in stress can be reduced, then many advantages can be expected.

‘Low Relaxation’ wire and strand exhibit a relaxation loss not greater than 2.5% after 1000 hrs at around 20 degrees centigrade. when initially loaded to 70% of the specified minimum breaking strength, as compared to 5% for ‘Normal Relaxation’ of stress-relieved wire and strand. There are certain applications where Normal Relaxtion (NR) wires are more suitable. We supply the same as per prescribed specifications, if required by the customer.

- Up to 10% reduction in steel and concrete consumption for projects can be achieved, resulting in reduced cost of project

- A significant reduction in the number of anchorages, ducts and wedges used for the projects

- Low relaxation ensures that no noticeable loss of tension will occur in time, therefore ensuring a long lasting compressive force on concrete.

- Lower relaxation loss, which is 2.5% max after 1000 hrs

- Hot Stretching process during manufacturing ensures almost straight strands, hence eliminating the extra post-straightening treatment

- Higher fatigue and corrosion resistance

- Uniform stress-strain relationship

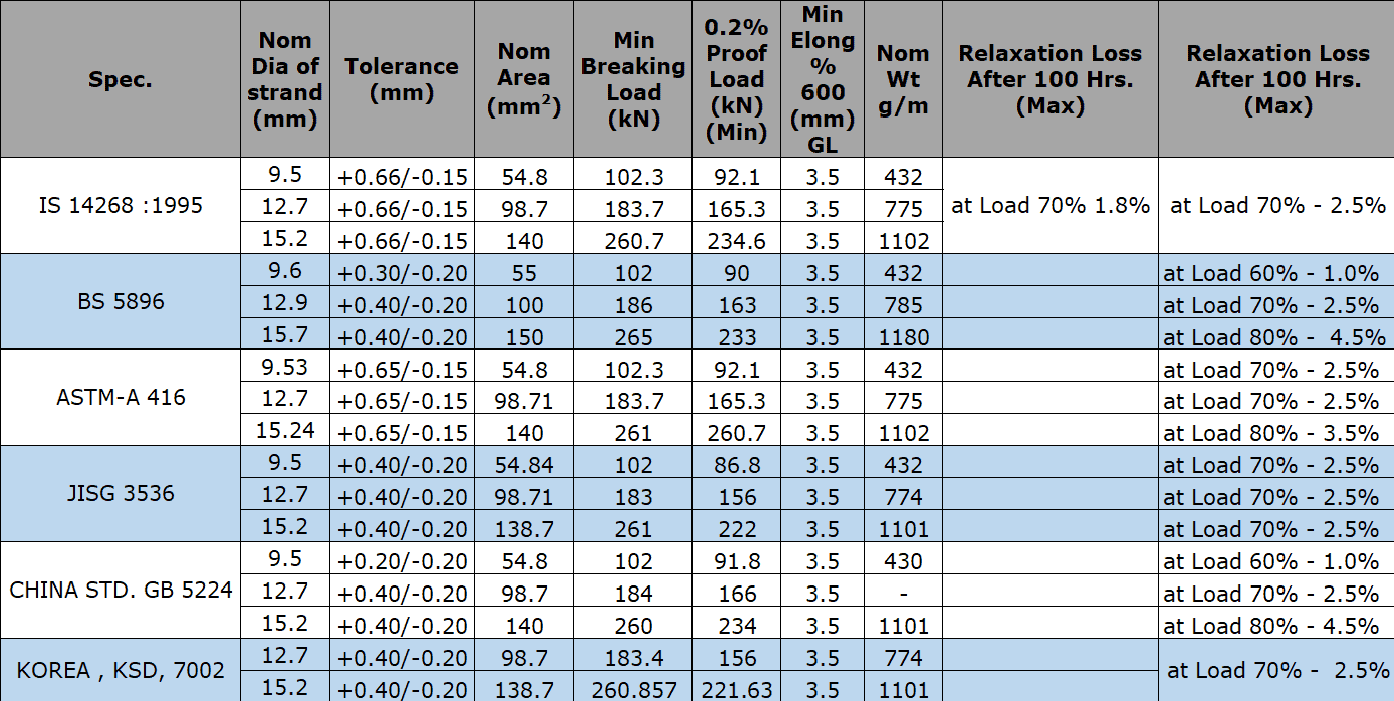

Standards

Variants

Low Relaxation PC Strand

(IS:14268)

We are presenting a wide assortment of LRPC Strands. Low relaxation PC stranded wire is the concept of pre-stress steel strands loosing applied stress in mathematical proportion with the passage of time when embedded in concrete.

Uncoated Stress Relieved Strand (LRPC)

(IS:14268)

We are offering a wide assortment of uncoated Stress Relieved Strand as per IS and International Standards. The products offered by us are widely demanded by the clients for their availability in various sizes and dimensions. These products are suitable for various applications and available in both personalized as well as customized patterns.

Features

– High performance

– Effectiveness

– Most reasonable prices

Key Clients

Packaging

- 7 wire strands (IS 14268)

- Weight – 2000 – 3500 kg

- Inner Diameter – 900 mm

- Outer Diameter – 1000-1300 mm

- Coil Width- 750 mm

The Miki Steel strands are packed in reel-less coils. With strapping in six places & one circumferential high tensile strap around the coil. The starting of the strand is separately identified and can be easily located on the coil.

Miki Steel coils are first wrapped with stretch wrap or VCI. Another layer of HDPE laminate wrapping for protecting the coil through transportation. Standard colour orange.

If required by the client, the coils are coated with a water soluble coating. This increases the storage life of the coils and can we washed off by spraying water on to the coils.

The coils can be made to weights of 2MT to 3.5MT as per the customers requirement & specification. Each coil comes with a secured MIKI STEEL tag which states the weight & serial number of the coil.